We recognize that it is important to deliver safe and secure foods to customers. Therefore, we conduct self-imposed radioactive-material test.

Unit of Measurement : Bq(becquerel)/kg

Lower limit – 8Bq

| Objectives for examination | Measure amount of radioactive cesium every day which is contained in raw material fish, auxiliary material, finished products, and water. |

|---|

| Level of shipping criteria | Legal compliance |

|---|

We judge that the level of shipping criteria can respect legal compliance by setting our company examination criteria at under 50Bq/kg.

A second examination is made if a product exceeding company’s criteria should be found.

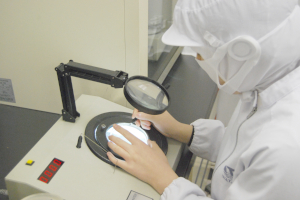

During examination, a sample is stored and examined in a container at a lead shielded sample chamber without effect of radiation, and amount of radiation from a sample is examined.

|

|

|

||

| gamma ray spectrometer | gamma ray spectrometer | measured data |

RC2 Scintillation radioactive ray counter

Unit of measurement : μSv(sievert)/h

To avoid environmental contamination, we conduct fixed-point observation of our premises and outside air, and form the data.

In a case value exceeding Miyagi Prefecture’s criteria(0.23μSv/h) is found, we conduct decontamination work, and materials and equipments are decontaminated as well.

![]()

The idea of HACCP was developed in the 1960s in the US to ensure the safety of foods for space flights. Basically, HACCP consists of HA and CCP.

HA:Where are the hazards that may occur and impede the producing of safe food?

CCP:Where are the critical control points to defend against hazards in the producing process?

HACCP is a hazard preventive system based on hazard analysis. This system aims to minimize the occurrence of hazards by intensively controlling, recording and confirming critical control points within the entire producing process from the arrival and storage of raw material to the producing/processing and shipping of products.

|

|

|

・Clean work uniform

・Rubber apron ・High boots ・Disposable facemask ・Hair net and cap ・Arm sleeves ・Disposable rubber gloves |

・Automatic water

・Liquid soap ・Nailbrush ・Jet towel hand dryer ・Alcoholic disinfectant ・Walk-through boot washing basin

According to the predetermined procedures, employees clean their hands and enter the workplace. While working, they wear disposable non-permeable gloves and do not touch things with their bare hands. In addition, cutting boards and knives used in manufacturing/processing are water cleaned and disinfected, and replaced periodically.

|

|

|

|

At the factory, we hold a meeting every morning. When employees come to the factory in the morning, they are checked for their health condition, and those who have a possibility of sickness or hand/finger injury are transferred from the production line. They do not engage in what brings contamination until their symptoms cease and they return to good condition.

|

When entering the factory, employees use a roller to remove hair, etc., if any, from the surface of the work wear by checking in the mirror. Also, when they enter the final packaging line, they use a roller again to ensure that foreign matter does not enter.

|

|

|

|

We have a quality control room within the company and conduct voluntary inspections in addition to mandatory HACCP inspections everyday.

[Inspection item] Total number bacteria Coliform group bacteria Escherichia coli Vibrio parahaemolyticus Salmonella |

We have a year-through training program for employees working in the factory. The program curriculum extends from voluntary inspection to safety/hygiene in the factory to improve the employees’ level.

|

Copyright © WATARAI All Rights Reserved